Metal Roofing: Sustainable Choices for Food Processing Plants: 99 exch, Lesar 247.com, Yolo247 login

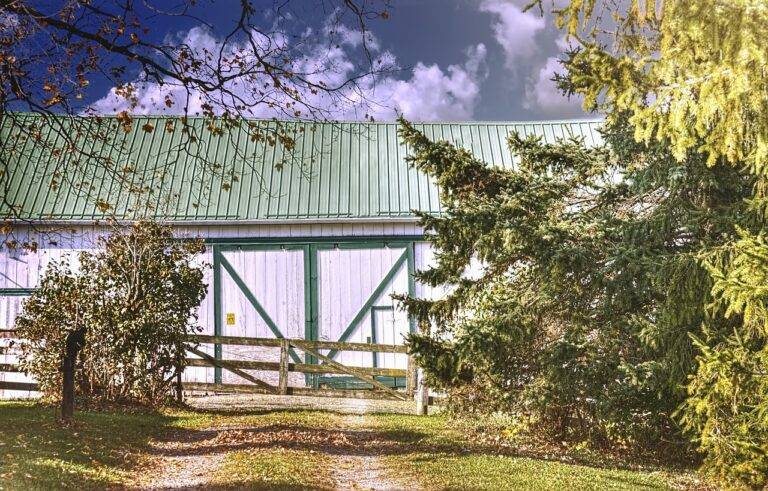

99 exch, lesar 247.com, yolo247 login: Metal roofing is becoming an increasingly popular choice for food processing plants looking to make sustainable decisions when it comes to their facilities. With a variety of benefits, from energy efficiency to durability, metal roofing is a smart choice for businesses looking to reduce their environmental impact while also saving money in the long run.

One of the key reasons why metal roofing is a sustainable choice for food processing plants is its longevity. Unlike traditional roofing materials such as asphalt shingles or tiles, metal roofing can last up to 50 years or more with proper maintenance. This means that businesses won’t have to worry about replacing their roof every 20-30 years, reducing the amount of waste that ends up in landfills.

Metal roofing is also highly energy-efficient, which can lead to significant cost savings for businesses in the long run. Metal roofs are reflective, meaning they can help reduce the amount of heat that is absorbed into a building, keeping it cooler in the summer months. This can lead to lower energy bills as businesses won’t have to rely as heavily on air conditioning to maintain a comfortable temperature inside their facilities.

Additionally, metal roofing is highly durable and can withstand harsh weather conditions, such as high winds, heavy rain, and snow. This means that food processing plants won’t have to worry about frequent repairs or replacements due to weather-related damage, further reducing their environmental impact and saving money on maintenance costs.

In terms of sustainability, metal roofing is also a recyclable material, meaning that when a metal roof does eventually need to be replaced, the old material can be recycled and used to create new roofing materials. This helps reduce the amount of waste that ends up in landfills and conserves natural resources in the process.

Overall, metal roofing is a sustainable choice for food processing plants looking to make environmentally-friendly decisions that can also benefit their bottom line. With its longevity, energy efficiency, durability, and recyclability, metal roofing is a smart investment for businesses looking to reduce their environmental impact and save money in the long run.

### Benefits of Metal Roofing for Food Processing Plants

Metal roofing offers a wide range of benefits for food processing plants looking to make sustainable choices for their facilities. Here are just a few of the key advantages of metal roofing:

– Longevity: Metal roofing can last up to 50 years or more with proper maintenance, reducing the need for frequent replacements and decreasing waste.

– Energy Efficiency: Metal roofs are reflective and can help reduce the amount of heat absorbed into a building, leading to lower energy bills and a reduced carbon footprint.

– Durability: Metal roofing is highly durable and can withstand harsh weather conditions, reducing the need for frequent repairs and replacements.

– Recyclability: Metal roofing is a recyclable material, meaning that old roofing materials can be recycled and used to create new roofing products, reducing waste and conserving natural resources.

– Cost Savings: While the upfront cost of metal roofing may be higher than traditional roofing materials, the long-term cost savings in terms of maintenance and energy efficiency make it a cost-effective choice for food processing plants.

– Aesthetics: Metal roofing comes in a variety of styles and colors, allowing businesses to choose a roofing solution that complements the overall design of their facilities.

### How to Choose the Right Metal Roofing for Your Food Processing Plant

When it comes to choosing the right metal roofing for your food processing plant, there are a few key factors to consider. Here are some tips to help you make the best decision for your facility:

– Material: There are several types of metal roofing materials to choose from, including steel, aluminum, copper, and zinc. Each material has its own advantages and disadvantages, so it’s important to do your research and choose the material that best fits your needs.

– Style: Metal roofing comes in a variety of styles, including corrugated, standing seam, and metal shingles. Consider the overall design of your facility and choose a style that complements the aesthetic of your building.

– Coating: Metal roofing can be coated with a variety of finishes to enhance durability and weather resistance. Consider the climate of your location and choose a coating that will help protect your roof from harsh weather conditions.

– Installation: It’s important to choose a reputable roofing contractor with experience installing metal roofing. Proper installation is key to ensuring the longevity and performance of your roof.

– Maintenance: While metal roofing is low-maintenance compared to traditional roofing materials, it’s still important to keep up with regular inspections and maintenance to ensure the longevity of your roof.

### Case Studies: Food Processing Plants That Have Chosen Metal Roofing

Many food processing plants have already made the switch to metal roofing and are reaping the benefits of their sustainable decision. Here are a few case studies of food processing plants that have chosen metal roofing for their facilities:

1. Green Valley Foods: Green Valley Foods, a family-owned food processing plant in California, recently replaced their old asphalt shingle roof with a metal roofing solution. The new metal roof has helped reduce the plant’s energy bills by 20% and has improved the overall energy efficiency of the facility.

2. Organic Harvest Co-op: Organic Harvest Co-op, a sustainable food processing plant in Oregon, chose a standing seam metal roof for their facility. The new roof has helped reduce the plant’s carbon footprint and has decreased their maintenance costs over time.

3. Fresh Start Foods: Fresh Start Foods, a food processing plant in New York, installed a corrugated metal roof on their facility to improve durability and energy efficiency. The new roof has helped reduce the plant’s energy consumption by 15% and has increased the overall lifespan of the facility.

### FAQs

1. How long does metal roofing last?

Metal roofing can last up to 50 years or more with proper maintenance, making it a highly durable roofing solution for food processing plants.

2. Is metal roofing energy-efficient?

Yes, metal roofing is highly energy-efficient. Metal roofs are reflective and can help reduce the amount of heat absorbed into a building, leading to lower energy bills and a reduced carbon footprint.

3. How much does metal roofing cost compared to traditional roofing materials?

While the upfront cost of metal roofing may be higher than traditional roofing materials, the long-term cost savings in terms of maintenance and energy efficiency make it a cost-effective choice for food processing plants.

4. Can metal roofing be recycled?

Yes, metal roofing is a recyclable material. When a metal roof needs to be replaced, the old material can be recycled and used to create new roofing products, reducing waste and conserving natural resources.

5. What types of metal roofing materials are available?

There are several types of metal roofing materials to choose from, including steel, aluminum, copper, and zinc. Each material has its own advantages and disadvantages, so it’s important to do your research and choose the material that best fits your needs.